ALL PROJECTS > CORPORATE > KARUNA EAST & WEST BUILDINGS

ALL PROJECTS > CORPORATE > KARUNA EAST & WEST BUILDINGS

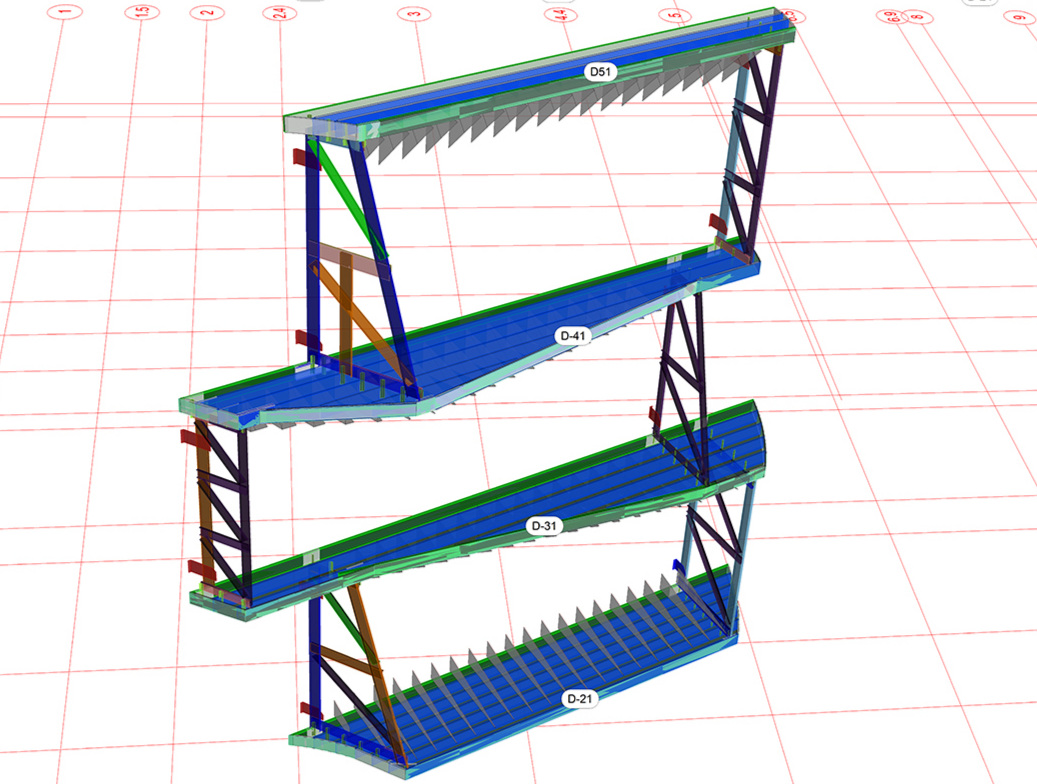

CFS Truss and Curved Deck Assemblies Deliver Apertures at Karuna East & West Buildings

/ PROJECT

Karuna East & West Buildings at One North | Portland, OR

/ SCOPE

Develop, fabricate and deliver cold-formed steel structural trusses and floor panels to construct the building apertures for the mixed-use, commercial development designed to Passive House standards.

Kit-of-parts aperture framing system fastened back to primary structure at 4 specified points per floor.

Streamlined framing profiles with 1/8” tolerance to set the geometry and meet the architect’s design intent.

10-month turnover schedule to meet owner-tenant agreement.

/ SOLUTION

Together with the Architect and Design Build General Contractor, Radius Track developed and 3D modeled a cold-formed steel stacked deck and truss system to meet the structural design criteria and deliver the cantilevered apertures according to the design intent. Framing component sequencing followed the installation schedule.

Pre-assembled trusses provided rapid installation to primary structure at each floor.

Custom shaped and cut deck framing with assembly instructions allowed for efficient unitization on site.

Data exported from the 3D model to robotic survey equipment facilitated precise field layout.

/ RESULT

Radius Track Corporation developed the cold-formed steel framing system and fabricated the structural components that shaped the apertures. The cold-formed steel kit-of parts replaced a heavier red iron steel proposal, decreasing the overall weight by nearly 60%. The Radius Track truss and site unitized deck solution delivered the required ACCURACY and SAVED TIME AND MONEY.

/ PROJECT TEAM

Architect: Holst Architecture

Structural Engineer: Froelich Engineers

General Contractor: R&H Construction Co.

Cold-formed Steel Framing System: Radius Track Corporation

/ VIDEO

“The Radius Track Corporation solution was so precise and their ability to prefabricate materials ahead of time saved us money and saved us time. It was the obvious choice. I look forward to using them again.”

– Andy Hernandez, Superintendent, R&H Construction (General Contractor)