ALL PROJECTS > CULTURAL > FROST MUSEUM OF SCIENCE

Digitally Design, Vet and Fabricate Metal Framing System for Patterned Tile Façade

/ PROJECT

Frost Museum of Science | Miami, FL

/ SCOPE

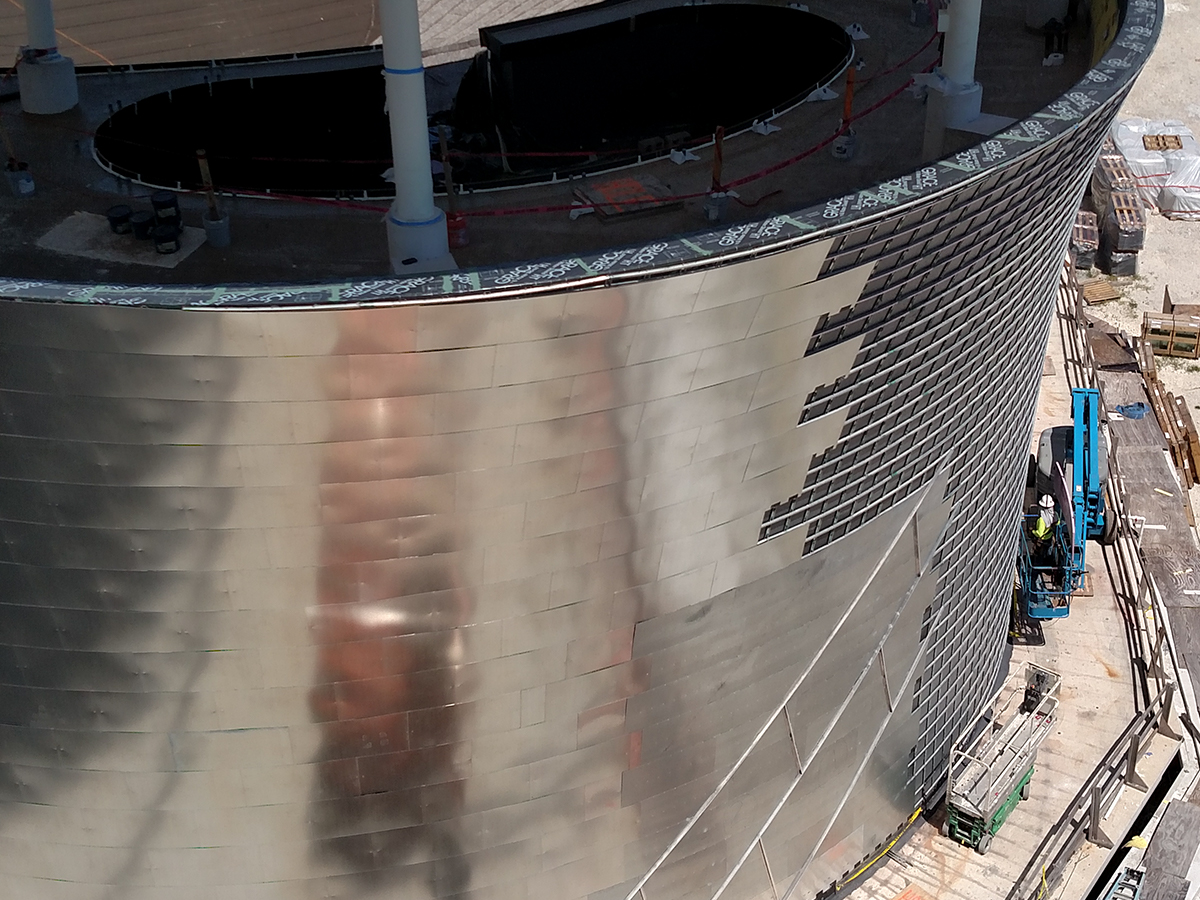

Work closely with the Architect and the Façade Installation Contractor to develop a cold-formed steel framing system to set the geometry for a compound curving façade of patterned tile with a 1/16” tolerance.

Framing system to create a vented cavity and help achieve Miami-Dade NOA for hurricane resistance.

Solution to overcome as-built structural conditions.

Streamlined framing profiles to set the geometry and deliver specified tolerance for the tile finish system.

/ SOLUTION

Radius Track developed a uniquely designed cladding sub-assembly which allows the two-way cold-formed steel framing system to move independently without causing failure to the patterned tile finish.

Custom cold-formed steel connectors support the loads individually and make installation easy and efficient.

Ventilated cavity separating the cladding and waterproofing allows drainage and evaporation.

Parametric modeling was used to meet the intent of the patterned tile design.

Precision fabricated structural cold-formed steel framing elements were installation ready.

/ RESULT

Radius Track Corporation developed a process to input two-dimensional details, deploy them three-dimensionally and create a feedback loop to gain 360-degree exposure of the aquarium façade to ensure GEOMETRIC ACCURACY and SYSTEM PERFORMANCE.

/ PROJECT TEAM

Architect: Grimshaw Architects

AOR: Rodriguez & Quiroga Architects Chartered

Construction Manager: Skanska

Exterior Wall System Contractor: Kenpat

Cold-formed Steel Development & Fabrication: Radius Track Corporation

CFS Engineering: McClure Engineering Co.

/ AWARDS

2017 ENR Southeast Best Project Award; Category: Cultural/Worship

2018 AWCI Excellence in Construction Quality Award; Category: Steel Framing

/ VIDEO

“Assembling a core team to bring the right expertise at the right time is the key to the success of this project. To kick-off the effort, we agreed to start with an intensive three-day collaboration.”

– Paul Wolmarans, CEO, Kenpat USA (Contractor)